热轧板坯测宽及偏移检测系统

产品编号:STV7700

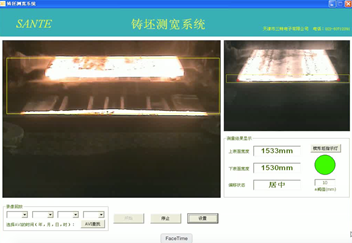

STV7700热轧板坯测宽及偏移检测系统为我公司研发的过程智能监控管理系统,可对热轧辊道上的板坯宽度及偏移量进行自动检测,保存相关信息保存;当钢坯的偏移量超出警界值时,系统会自动发出声光报警,提醒操作人员及时处理,消除生产隐患。这对企业提供信息化水平、促进安全生产以及提高劳动生产率将发挥积极作用。

1. Real-time monitor the movement condition of hot rolling slab.

2. Automatic measure both upper and bottom width of hot rolling slab.

3. Automatic detect offset

4. Automatically save data into system

5. The system can trigger alarm when deflect is found.

1. Advanced Width Measurement

The system is using two cameras to measure the width of slab. Unlike traditional laser width measurement, camera can minimize the disturbing from high heat, and the system not only can measure the top surface’s width but also the bottom. This will avoid the lost from uneven top and boom.

2. Intelligence Software

The system can send out alarm automatically when any deflect or offset being found. Operator can set a allowance value for deflection, deflection angel, and horizontal offset.

When deflect or offset is over the limit, the system will send out both visual and sound alarm to prevent accident.

3. Database

The system can save all video, and slab information into the system. It also can communicate with plant slab database.

|

Cooling Medium |

Cooling Air |

Inlet Pressure |

0.3~0.7 MPa |

|

|

Air Supply Pipe Diameter |

DN40 |

|||

|

Flow |

0.5M³/min |

|||

|

Cooling Water |

Pressure |

0.3~0.4MPa |

||

|

Flow |

1M³/h |

|||

|

Power |

Power Supply |

AC220V 50Hz |

||

|

Power Consumption |

1000W |

|||