Blast Furnace Top Thermal Imaging System

Series No. STV4900

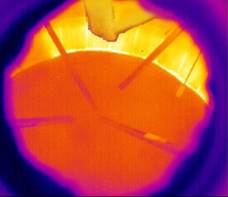

STV4900 Blast Furnace Top Thermal Imaging System is a system installed on the top of Blast Furnace, using thermal imager to capture the video of burden, airflow, swing chute of blast furnace. The system provides accurate temperature measurement with allowance of ±3 ºC.

1. Real-time monitoring of Burden surface and airflow distribution.

2. Real-time monitor the motion of swing-chute inside Blast Furnace.

3. 640×480 high-resolution camera.

4. Precisely temperature measurement with allowance of ±3°C

5. More than 300,000 temperature measurement points.

6. Automatic enter and withdraw system.

7. Online maintenance supported.

|

|

1. Real-time Monitoring at All Time

The system is using an infrared thermal imager, which can capture image at all time, this will provide video support when Blast Furnace is off-line for maintenance.

2. Deposit Dust Free Design

The system is using our company’s unique design. The protector has pre-set air guide groove,which offer the cooling air clean the lens while it blow through the whole protector.

3. Sharp Lens and High Resolution Camera

The system combines a 640×480 high-resolution needle-hole camera and a special coated heat resistance lens to ensure the sharpness of image.

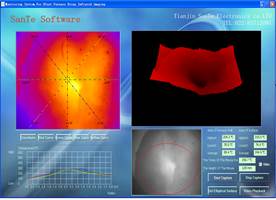

4. Intelligence Software

The intelligent software measures the temperature of the burden surface by process the data feedback from the camera, and generates a temperature profile. The software also can generate a 3D model of the burden surface. All data will be save to system automatically.

5. Advanced Protection

The system is adopted with automatic enter and withdraw system, when the supply of cooling medium is irregular, or the temperature inside the protector is higher than preset value, the system will automatically withdraw. This also makes on-line maintenance available. The system is using pneumatic cooling only.

6. Safety

The system applies a unique gate valve and ball valve. When the protector withdraws the gate valve and ball valve automatically close, to prevent the spill of coal gas. There is a check-valve structure, when the coal gas supply broken or sudden pressure drop. The structure can prevent the spilling of coal gas.