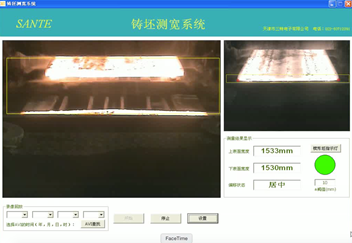

Slab Width Measurement and Offset Detection System

Series No. STV7700

The system is our company’s intelligent process monitoring & management system, can automatically monitoring the width and displacement of billets on hot-rolling roller way, and can save related information; when the displacement is over than the limits, the system can send the sound-light alarm to remind the operators handle such issue in time; that, the production hidden troubles can be eliminated. The system has great active effects in improving enterprise information level, enhancing safety production and improving labor productivity.

1. Real-time monitor the movement condition of hot rolling slab.

2. Automatic measure both upper and bottom width of hot rolling slab.

3. Automatic detect offset

4. Automatically save data into system

5. The system can trigger alarm when deflect is found.

1. Advanced Width Measurement

The system is using two cameras to measure the width of slab. Unlike traditional laser width measurement, camera can minimize the disturbing from high heat, and the system not only can measure the top surface’s width but also the bottom. This will avoid the lost from uneven top and boom.

2. Intelligence Software

The system can send out alarm automatically when any deflect or offset being found. Operator can set a allowance value for deflection, deflection angel, and horizontal offset.

When deflect or offset is over the limit, the system will send out both visual and sound alarm to prevent accident.

3. Database

The system can save all video, and slab information into the system. It also can communicate with plant slab database.

|

Cooling Medium |

Cooling Air |

Inlet Pressure |

0.3~0.7 MPa |

|

|

Air Supply Pipe Diameter |

DN40 |

|||

|

Flow |

0.5M³/min |

|||

|

Cooling Water |

Pressure |

0.3~0.4MPa |

||

|

Flow |

1M³/h |

|||

|

Power |

Power Supply |

AC220V 50Hz |

||

|

Power Consumption |

1000W |

|||