Conveyor Belt Material Size Analysis System

Series No. STV7800

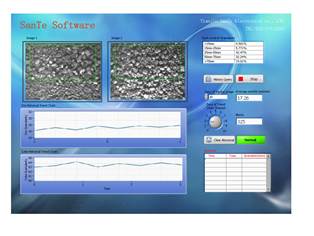

STV7800 Conveyor Belt Material Size Analysis System is a system installed on top of the conveyor belt, and capture images from moving belt. By analyze the data from our camera; our system will be able to give our size information of the material on the belt. The system provides much higher sample rate than screening method.

1. Real-time monitor all material on the conveyor belt.

2. Real-time analyze material size and display on monitor.

3. Automatically store data and image into the system.

4. Automatically send out alarm when irregular material appears on belt.

The system with the camera installed over the belt conveyor real-time collects and remotely displays the images, and perform the analysis and treatment with the PC image treatment technology; the system has the following properties:

1. Size Analysis

Real-time & on-line monitor the material size distribution.

2. Inspection of Coke Physical Properties

Automatically inspect the coke size, porous coke, black head and other physical properties.

3. Inspection of Belt Conveyor Safety

The software intelligently monitors the belt working conditions. When there are the belt deflection, large foreign material, belt tearing and other abnormal conditions, the system automatically alarms to avoid the production accidents.

4. Monitoring of Ore/Coke Return

The system software automatically monitors the ore/coke return to timely find the abnormal issues of sieve, to avoid the usable material being returned as waste, so the material utilization rate is improved.

5. Abundant Safety Sampling

The system on time & real-time collect the material images; the sampling quantity is abundant, the occasionally and danger of manual data collection are avoid, and the data accuracy is greatly improved.

|

Measurement precision |

Ore 1mm, coke 4mm |

|

Material linear speed |

2m/s |

|

Accuracy |

> 95% |

|

Power supply |

220V/50Hz AC 1.5KW |

|

Compressed air |

0.4~0.7 MPa |

|

Air supply pipe diameter |

DN25 |

|

Air flow |

1.0 M³/min |